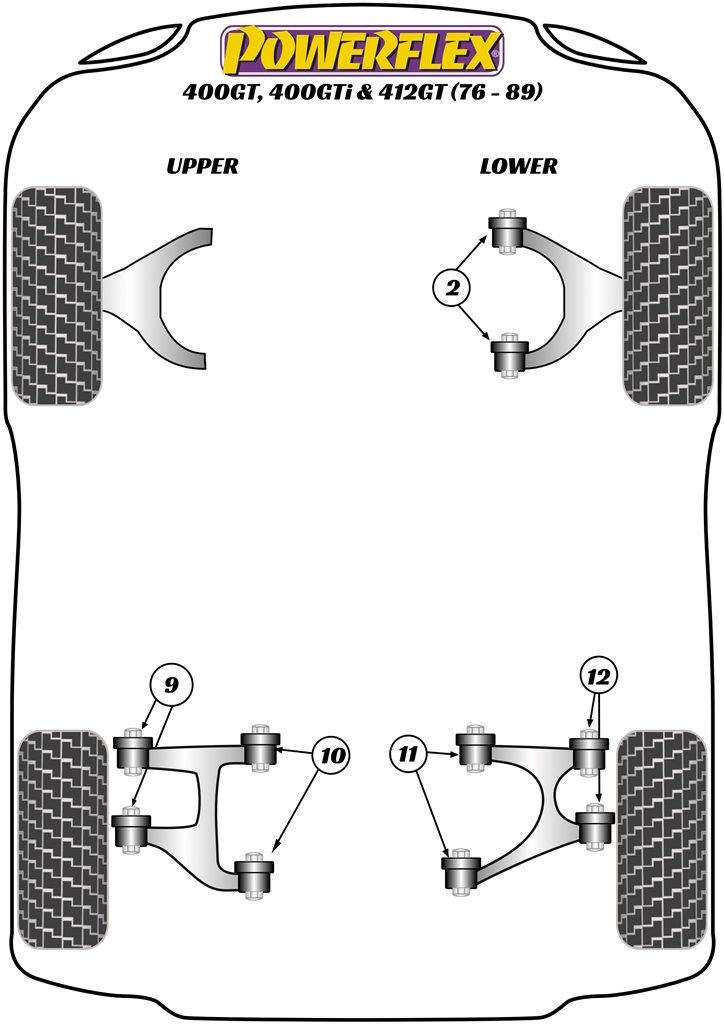

PowerAlign Wheel Mounting Guide Pin Powerflex Polyurethane Bush Road Series Ferrari 400GTi, 412GT (1976 - 1989) PF99-514-15

- Number on diagram:

PowerAlign Wheel Mounting Guide Pin Powerflex Polyurethane Bush Road Series Ferrari 400GTi, 412GT (1976 - 1989) PF99-514-15

Powerflex was founded in Great Britain in 1996. The company has extensive experience in the field of car suspensions. Mix of design skills and manufacturing techniques has led to the creation of a wide range of high-quality polyurethane products.

Why use Powerflex polyurethane bushings?

Polyurethane is definitely more resistant to wear than rubber. Polyurethane bushings last longer, even under extreme operating conditions.

They are stiffer than rubber, providing better handling and control of the vehicle, especially during cornering and braking.

Powerflex Polyurethane Bush for:

Ferrari 400GTi, 412GT (1976 - 1989)

Index: PF99-514-15

Diagram number:

Dimensions: brak danych

Weight (g): 122

Package quantity: 1

Quantity required in car: 1

Original part number: 9A700773300

EAN number: 5055676559104

Lifetime warranty

Special grease included

Additional information:Available singularly to suit a specific vehicle or as a handy 4-piece workshop kit, our new PowerAlign Wheel Mounting Guide Pins are designed to allow the safer mounting and easy alignment of heavy alloy wheels on most common cars to use lug bolts. The individual pins come supplied in a reusable twist tube and the 4-piece workshop kit is supplied with a steel storage case for pride of place in your toolbox. Simply thread the appropriate pin size into one of the bolt holes on the wheel hub. The wheel can then be lifted and placed on the guide pin, and easily slid into place on the hub; keeping the bolt holes aligned for other bolts to be inserted and tightened.This reduces the awkward and back-straining process of holding the wheel in place with one hand whilst lining up and threading in the first bolt; thus, reducing the risk, hassle, and strain of mounting wheels.Proven using simulated and real-world testing, the new mounting pins use high-strength CNC-machined AISI 303 Stainless Steel, some 50% stronger than plated mild steel, to ensure durability and resilience in a workshop environment, and are supplied with colour-coded 3D-printed protective sleeves for ease of identification and anodised 2011-T6 aluminium caps to absorb knocks and prevent damage to the wheel, unlike others on the market. Please click here to view all sizes available and for a wider-reaching application list in the form of a new user-friendly drop-down search function.

Supplementary information:

The individual pins come supplied in a reusable twist tube and the 4-piece workshop kit is supplied with a steel storage case for pride of place in your toolbox.

Simply thread the appropriate pin size into one of the bolt holes on the wheel hub. The wheel can then be lifted and placed on the guide pin, and easily slid into place on the hub; keeping the bolt holes aligned for other bolts to be inserted and tightened.

This reduces the awkward and back-straining process of holding the wheel in place with one hand whilst lining up and threading in the first bolt; thus, reducing the risk, hassle, and strain of mounting wheels.

Proven using simulated and real-world testing, the new mounting pins use high-strength CNC-machined AISI 303 Stainless Steel, some 50% stronger than plated mild steel, to ensure durability and resilience in a workshop environment, and are supplied with colour-coded 3D-printed protective sleeves for ease of identification and anodised 2011-T6 aluminium caps to absorb knocks and prevent damage to the wheel, unlike others on the market.

Please click here to view all sizes available and for a wider-reaching application list in the form of a new user-friendly drop-down search function.